LOTO procedure

If you've ever taken your car to an oil change service, the first thing the mechanic will ask you to do is take the keys out of the ignition and put them on the dashboard. It is not enough to make sure that the car is not moving - before putting your hands on the oil pan, you need to make sure that there is no chance of starting the engine. In this way, the mechanic protects himself - and you too - eliminating the possibility of human error.

According to the Safety block of internal corporate requirements of WeGA, each plant of the Atlantic Group is already at a basic level obliged to develop and implement regulations requiring the shutdown and blocking of all energy sources during the repair or maintenance of equipment, namely the LOTO system.

What is this?

What is this?The LOTO system (abbreviation for Lockout/Tagout) is a scheduled safety procedure that removes the power source of equipment during maintenance or repair work. This procedure ensures that workers are protected from the risks of electric shock and injury from other hazardous energies.

Systems consist of several main elements:

Blocking device (blocker) - designed to securely fix the energy source in a certain position;

Tag - contains information about the type of work, the start and end time of work, the person in charge, etc.;

Padlock - serves to lock the blocker or directly to the energy source (if there is a built-in lock).

How it was?

How it was?

At the beginning of 2022, a large-scale work was carried out to introduce the LOTO procedure at our plant. The development of the LOTO system took place in three main stages:

Description of procedures

Together with the maintenance and repair team (MRO) and a specialized external organization, the entire procedure for blocking hazardous energy was described. At this stage, the preparation of a general provision and LOTO instructions was carried out, defining the procedure for blocking each piece of equipment, checking the shutdown, discharging hazardous energy, as well as other documentation.

Implementation of the LOTO system

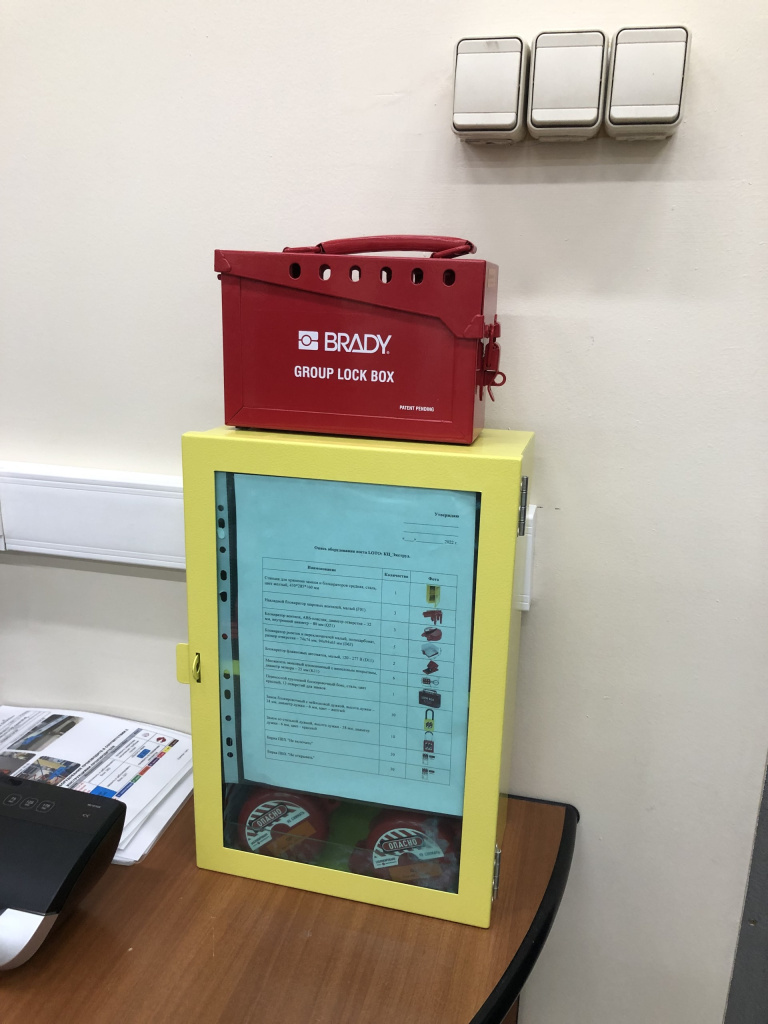

All the necessary LOTO equipment was purchased, the storage location was determined and prepared, those responsible for the equipment and the application of LOTO procedures in practice were identified

Обучение сотрудников

Обучение сотрудниковThe entire team of the maintenance and repair group was trained on the correct application of special procedures for blocking production equipment with the acceptance of an offset. And every new member of the team also undergoes mandatory training.

At the moment, our factory has its own LOTO protection for servicing all equipment. And we can be sure that these simple little devices protect our colleagues from big dangers every day!